If you work with horses, dogs, or outdoor-sports equipment long enough, you’ll eventually find that the ability to cut and reseal nylon webbing is a necessity to keep your tack and equipment safe, tidy, and well fit. Resealing edges prevents the fraying that can lead to strap failure if allowed to fray unchecked. This method works for nylon webbing, polypropylene webbing (aka “polypro”) and polyester braid.

There are a few ways to create new sealed edges, but this is the most simple method. Larger heat sources can be used, but a candle or lighter is sufficient. Caution: This tutorial involves working with open flames. Fire is dangerous. Proceed with caution. Work in a safe area on a stable surface and at no point allow the flame to touch your webbing, tools, or work surface.

Tools you’ll need:

1. sharp scissors

2. Candle or lighter

3. Webbing to be cut and resealed

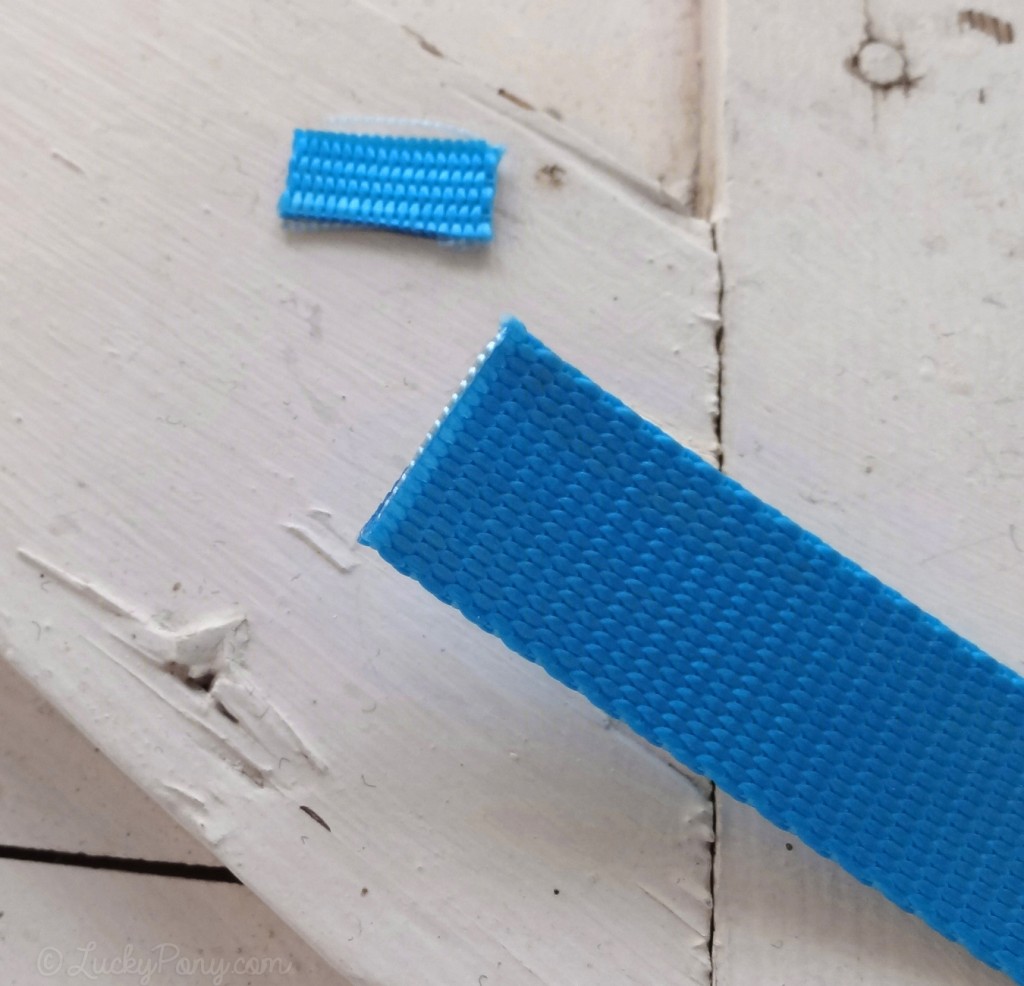

First, trim any frayed tips off your nylon. The turquoise nylon in my picture has a pretty clean edge, but I’ve illustrated this step anyway. Be sure and cut all the frayed portion off, creating a new edge where the braid is still tight:

New clean edge ready to be sealed:

To seal the end of your nylon strap, hold the end of your webbing about 1/4 inch away from a candle flame. If using a larger flame, you may not even need to hold the nylon that close. too close, and your nylon will blacken and potentially catch fire. The heat radiating off the tiny flame will be enough for the nylon to begin to melt at about one-quarter inch. Move your nylon so the entire edge melts.

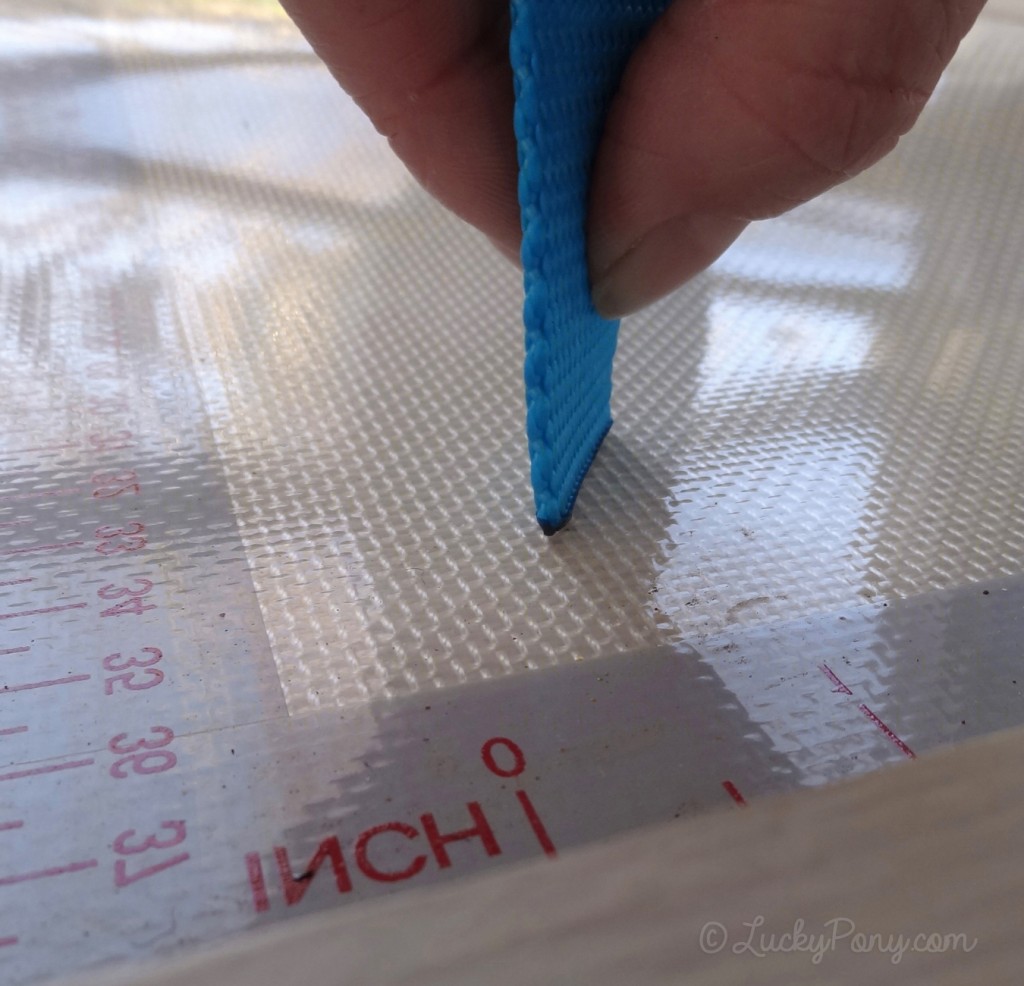

This step is optional, but if you desire a straight, flat edge to your nylon, similar to what commercial cutters and sealers create, you can take your nylon, while still very hot, and press the melted edge onto a silicone or teflon surface until cooled. This will mold the melted nylon into a clean edge.

These illustrated steps for neatly sealing nylon webbing can be a lifesaver when fitting halters or dog collars to animals smaller than the product was intended for.

Leave a Reply